Global efficiency

Serving quality diagnostic solutions to 14m patients annually

With the industry’s most extensive vertically-integrated manufacturing network, our unique size allows us to take our solutions further.

Curium’s unrivaled logistics and distribution network makes it possible to provide our 6000+ global customer-base with outstanding reliability and superior service. Crucially, this means our diverse portfolio of more than 50 radiopharmaceutical products is helping to improve the lives of 14 million patients each year.

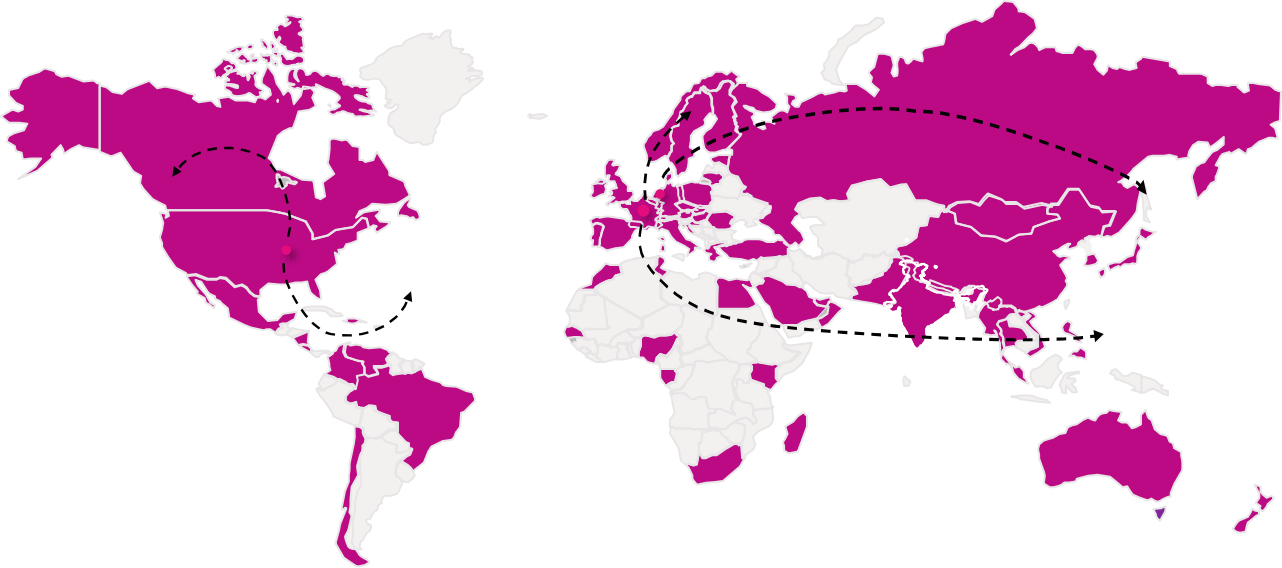

A worldwide presence

Global reach with local support

With a head office in Paris and offices around the globe, we are a trusted partner to public and private hospitals, radiopharmacies and imaging centres in over 60 countries worldwide.

Across our vast global network, our 2,000-strong employee base is committed to upholding our stringent quality standards, while ensuring every customer benefits from an exceptional level of service.

Driven by integrated efficiency

We have an unrivalled global commercial footprint with sophisticated distribution infrastructure with an ability to ship products major markets across the globe.

We employ over 25 sales and marketing personnel in North America and 70 personnel across Europe and rest of the world. We have direct presence in China, India, Turkiye, Mexico and a distributor network panning Middle east, Africa, Australia, Latam and Asia Pacific.

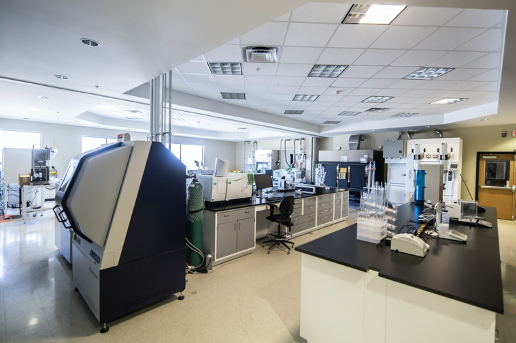

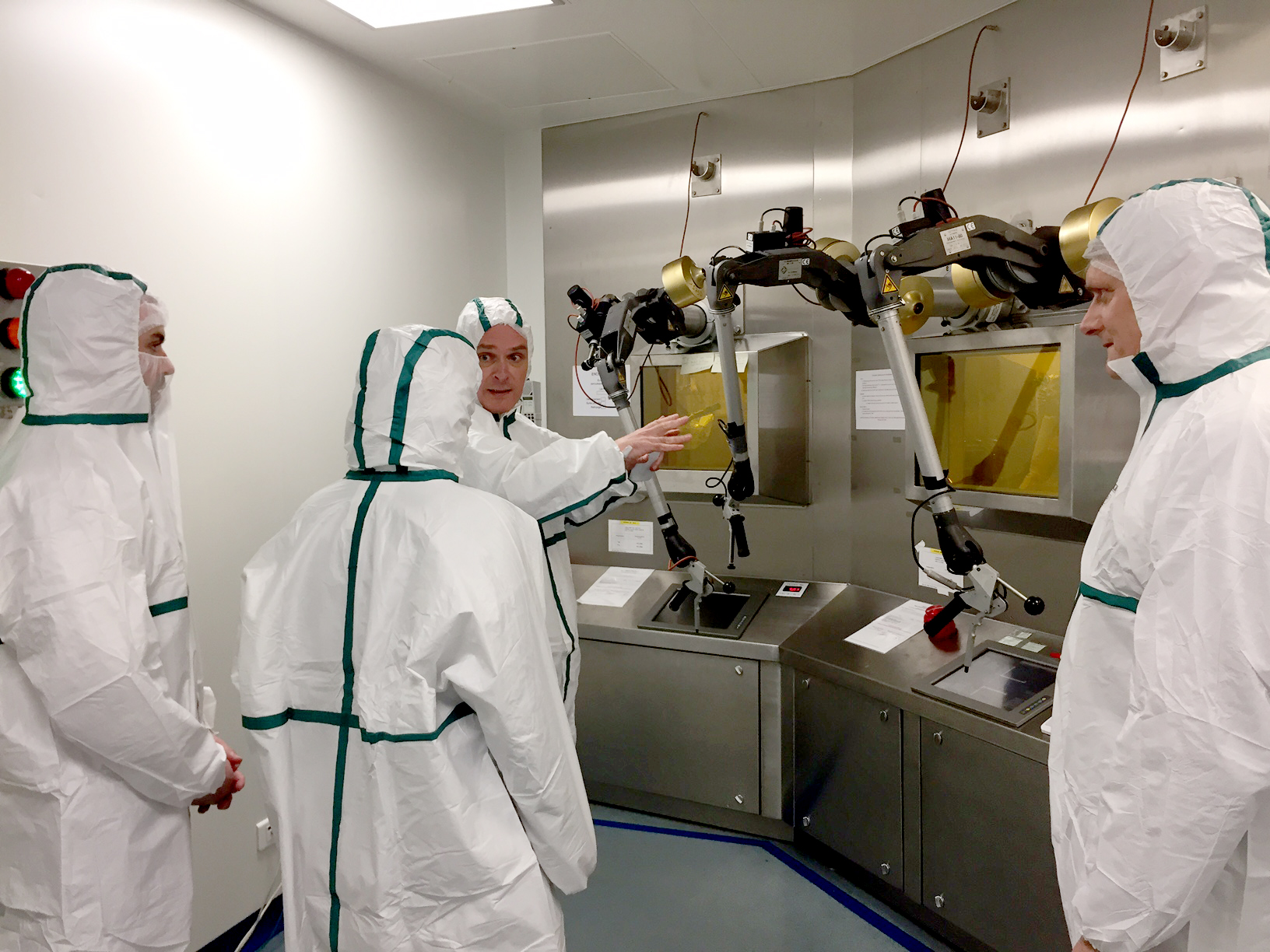

Our network is the largest vertically-integrated radiopharmaceutical manufacturing network in the nuclear medicine industry. But what does this mean for our customers?

- We can supply our trusted products to more locations, delivering diagnostic and therapeutic solutions for life-threatening diseases

- We can ensure a stable isotope supply, providing outstanding service reliability for our partners.

- We can focus on developing innovative new products that allow our customers to succeed while transforming the nuclear medicine industry.

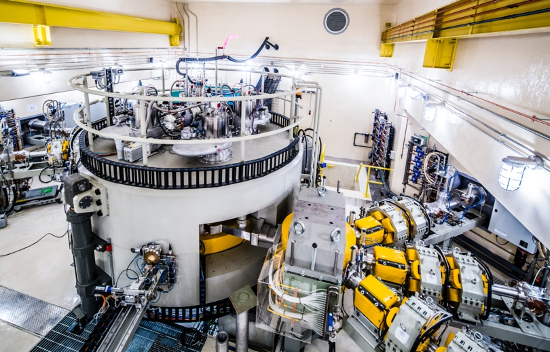

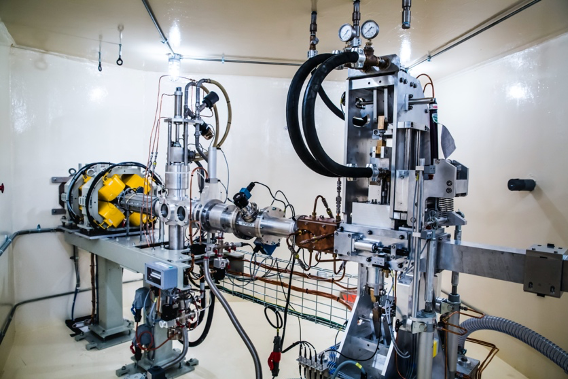

Nuclear manufacturing footprint

Maryland Heights, Missouri, United States

- Expertise in manufacturing reactor and cyclotron based isotopes and cold kits

- State of the art and nuclear Tc generator line in the US

- 6 cyclotrons currently in operation

- Aseptic suite for manufacturing cold kits

Noblesville, Indiana, United States

- Commercial 70 meV cyclotron

- Six beam lines and 10 hot cells

- Capability to produce a broad range of cGMP, clinical, industrial, and research radioisotopes

Petten, The Netherlands

- Captive bulk-Moly processing capacity – one of the largest in the industry

- Capabilities to manufacture reactor and cyclotron based isotopes + cold kits

- 2 cyclotrons currently in operation

- New state of the art fill-line

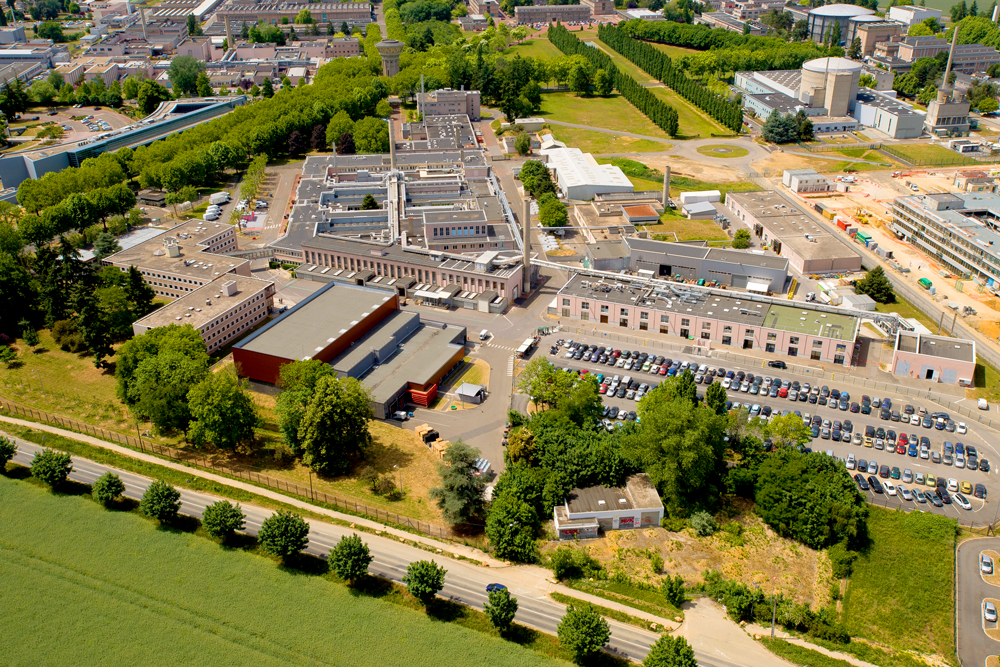

Saclay, France

- Capabilities to manufacture reactor and cyclotron based isotopes + cold kits

- 2 cyclotrons currently in operation

- Sterile manufacturing capabilities for cold kits including aseptic and terminal sterilisation

PET & SPECT explained

SPECT (Single Photon Emission Computed Tomography) scans use radioactive pharmaceuticals administered to patients in order to create 3D images that help diagnose a variety of diseases across oncology, cardiology, neurology, and other areas. A special camera or set of cameras rotate around the patient and detect the emissions from the radiopharmaceutical to create a cross-sectional image from the single photon that is emitted at a time from the radioisotope.

Like SPECT, PET (Positron Emission Computed Tomography) is a nuclear imaging technique that uses radioactive pharmaceutical administered to patients to create 3D images. However, PET drugs emit a single positron that when interacting with an electron shortly after emission has two photons being created and emitted at the same time 180 degrees from each other. Two or more cameras then detect the emissions and create the image based on the timing of when the two photons hit the cameras.

The most important difference between the two technologies from a manufacturing perspective is that the most often used isotope for PET scanning (F18) decays in a shorter time frame compared to the most often used isotope used for SPECT imaging (Tc99m). So F18 that decays with a 110-minute half-life, will only have half of the activity it started with after about two hours versus Tc99m that will have half of the activity it started with after 6 hours.

This means Curium’s PET facilities must be located close to our customers, whereas facilities that distribute radiopharmaceuticals used for SPECT imaging can ship to farther distances.